XCMG Machinery (SHE: 000425, "XCMG") is proud to announce that the Company has helped construct four of China’s mega projects that refreshed the world’s records for its scale and complexity. These achievements marked significant milestones for XCMG, proving its globe-leading engineering and design prowess to develop high-end mechanical equipment that empower China to elevate the country’s infrastructural developments to a new high.

Paving the Way for China's Underwater Tunnel with the Largest Diameter

XCMG’s high-end equipment for road construction provided a comprehensive and efficient solution for the Ma Wan Cross-sea Channel project, Shenzhen's first cross-sea tunnel spanning over 8 kilometers, which is a mammoth project that involves the construction of roads, tunnel, sponge city, as well as electrical and landscape engineering. Its vast scale and complex hydrogeological conditions add to the construction challenges, placing heavy demands on the reliability and adaptability of construction machinery.

Equipped with a new-gen M30B anti-torsion screed designed to boost anti-torsion and bending capability, XCMG's RP1355HDIV paver showcased its outstanding performance, ensuring uninterrupted workflow in laying down an asphalt layer with a width of 11.5 meters and a thickness of 5 centimeters. Versatile and powerful, the machine can meet various construction needs with its paving width ranging from 3 meters to 13.3 meters.

XCMG's XD135TIV road roller raises the bar of high-end tandem rollers with its 67Hz high-frequency vibration technology and a dual-frequency dual-amplitude vibration system. The roller's "soft start-stop" technology ensures smooth operation, effectively solving the challenge of material build-up and the formation of road lumps.

Contributing to a World-Class Cross-Sea Cluster Project

XCMG's XD135TOSIV oscillating roller played a crucial role in the building the undersea tunnel of Shenzhen-Zhongshan Link, a part of a trans-sea cluster project whose construction difficulty outpaces the world’s longest cross-sea bridge, the Hong Kong-Zhuhai-Macao Bridge. Featuring a two-way eight-lane design and spanning a length of six kilometers, the tunnel's closed environment, coupled with high temperatures, high humidity, poor ventilation, and its extensive width and length, posed challenges to the construction of the tunnel's asphalt road surface, the last and a critical component of the project.

Designed to boost efficiency and ensure a smoother, more stable compaction process, XD135TOSIV comes with optimized oscillation parameters and is capable of completing the compaction of paving materials within one hour of production. Thanks to its new technology, the XD135TOSIV generates vibration in the horizontal direction, reducing lateral vibration to 15% of traditional machines, and mitigating the impact on immersed tube tunnels.

In terms of control, the XD135TOSIV is equipped with a “soft start-stop” feature which allows for smooth start-up and shutdown operations without jolts, preventing material build-up and ensuring smoother surface finish. The water sprinkling system can be adjusted based on requirements, preventing asphalt from sticking to the drums and segregation. Moreover, real-time monitoring of the equipment's operational status ensures optimal working conditions.

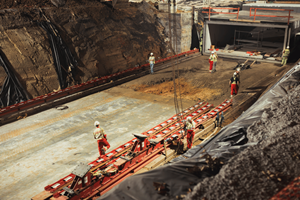

Laying Foundation for Shiziyang Bridge

The Shiziyang Bridge, which features the world’s largest bridge anchor, is a mega project that revolutionizes infrastructure on a global scale. Once completed, the Shiziyang Bridge will set five world records in the category of double-deck suspension bridges. Constructing the anchor involved the complex task of hoisting the steel reinforcement template and the annular reinforced concrete lining. Four XCMG cranes, which include the XGT7026-12S1 and XGT7528A-18S1 models, were deployed, working in tandem seamlessly to ensure fast progress and interrupted anchor construction. Over nearly 200 days of faultless operation, XCMG’s machinery was pivotal in ensuring the high-quality completion of the project.

XCMG's Innovative Solutions for the Hangzhou Bay Bridge

The S-shaped Hangzhou Bay Bridge is the longest ocean-crossing bridge in the world, built in some of the most complicated sea environments which make the construction task extremely difficult and risky. To overcome challenges, XCMG adopted an innovative approach developed collaboratively by XCMG and project personnel, ensuring the verticality of the drilled hole, and allowing for continuous construction for 240 hours. The deepest pile foundation hole reached up to over 156 meters.

With the pile diameter ranging from 2.5 to 2.8 meters and an average pile depth of 131 meters, XCMG was able to achieve a pile every three days. The remarkable pace of work testifies to the efficiency of XCMG's newly upgraded "F" series rotary drilling rigs which are fitted with high-powered engines, multi-gear drilling modes, ultra-high torque rotary heads, and large vertical plate box-type rotary platforms.