Backhoe Loader’ has been around as common construction equipment in urban engineering and small construction projects. Over the years this construction equipment market in India has gone through an evolution. The true development of the backhoe began in 1947 by the inventors that started the Wain-Roy Corporation of Hubbardston, Massachusetts. In 1947 Wain-Roy Corporation developed and tested the first actual backhoes. In April 1948 Wain-Roy Corporation sold the very first all hydraulic backhoes, mounted to a Ford Model 8N tractor, to the Connecticut Light and Power Company. With time there has been development in Productivity and performance. The backhoe loaders can now enable more Load, Dig and Doze productivity.

Backhoe loaders with fuel efficiency

CEV Stage IV backhoe loader range is powered by the ecoMax diesel engine. This model is environmentally friendly and comes with well-proven CRDI technology, a waste-gate turbocharger & a two-stage cooling EGR system. A unique feature of this engine is that it has a state-of-the-art combustion system that eliminates the need for any after-treatment, DOC (Diesel Oxidation Catalyst) or a DPF (Diesel Particulate Filter). This engine also has no deration at higher altitudes thus greatly benefiting customers and users in mountainous terrain. Backhoe loaders not only conform to the latest emission standards but will provide our customers with increased reliability, enhanced productivity and reduced operating costs enabling them to improve their profitability. The model more fuel-efficient in Eco mode and has 25% higher productivity in Plus mode as compared to the outgoing model. Its features like Auto Idle and Auto stop help to reduce fuel wastage and improve efficiency. Also, a high torque of 400 Nm and three Excavation Modes for different site conditions – Eco, Standard and Plus adds to the machine’s adaptability to meet output needs. The Hydraulic oil change period is now extended from 2,000 hours to 4,000 hours and Hydraulic oil quantity is reduced by 20 liters. This leads to a 15% lesser cost of periodic maintenance while improving the Total Cost of ownership.

Backhoe loader with an advanced telematics system

The backhoe loader is now guided with advanced telematics and Smart i-techsystem. The new intelligent products come with 12 percent improved mileage capability and also offer up to 22 percent lower maintenance costs. With these technologies, customers can get real-time information about the performance of a machine. The new models effectively manage the power demand with Intelli performance technology. The system effectively manages the energy demand from the hydraulic and powertrain to give a perfectly optimised performance. It also features an in-built auto-stop which automatically shuts the engine off after 6 minutes of inactivity to save fuel. The new backhoe loader is built with a spacious cabin, equipped with a new comfortable seat and an informative digital display to make it easy and comfortable to operate. Equipped with a Guide Me Home feature, the external lights of the machine stay on for 30 seconds for safety if the ignition is turned off in a dark environment. Powered by the ecoMAX engine (CEV Stage IV), it is equipped with 3 new innovative features that are, Easy Shift Gear, Semi-Kick Down Switch and Smooth Ride System Control that enhance productivity and reliability of the machine. The model comes with 4WD for better tractive efforts resulting in higher loading and dozing capabilities. The Variable Displacement Hydraulic Pump in these backhoes helps to reduce hydraulic losses resulting in better fuel efficiency. The backhoe provides excavation performance with higher digging forces with 6 in 1 bucket for various applications like dozing, grabbing, loading, grading etc.

Backhoe loader with FPT electronic engine

Efficient CEV-IV compliant FPT engine with high power and torque density coupled with proven transmission provides dozing, stockpiling and travel capability. The new model series offers FPT Electronic engine, which accurately controls the fuel injection to optimize the power delivery. FPT BS4 engine offers high performance with better power and torque management, better drivability and improved fuel efficiency. New generation hydraulics with VVP optimizes hydraulic oil flow as per load and improves fuel consumption up to 14%, which combined with ECO MODE and AUTO IDLE offer up to 20% better fuel economy. It also offers faster cycle time compared to gear pump, thereby improving productivity. Hydrocarbons (HC) and Nitrous Oxide (NOx) emission will also go down by seven times. It banks upon Diesel Oxidation Catalysts (DOC) to reduce harmful emissions dramatically. Electronic hand throttle and foot accelerator pedal, increased storage spaces, one touch idle, intuitive side cluster, comfortable and multi-adjustable operator seat in a spacious world-class cabin improve productivity for every operator. New age inclined pillar cabin provides better travel safety. Engine Protection Shutdown protects against unplanned breakdown and AV warning system makes operations safer, Backhoe loaders with fuel efficiency, Backhoe loader with an advanced telematics system, Backhoe loader with FPT electronic engine, Backhoe loaders for bigger projects, medium and small-sized projects.

Backhoe loader with Excellent Hydraulic System (EHS)

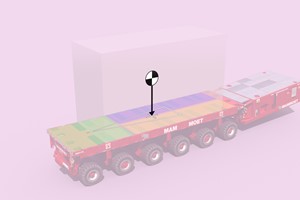

The modern backhoe Loader is powered by a new CEV-IV compliant fuel-efficient engine, reliable and an Excellent Hydraulic System (EHS) for high caliber performance. With a safe, comfortable, and spacious cabin for maximum operator comfort. Standard Loader Bucket 1.1 m3: Loader bucket is used for standard operations like loading and dozing applications. A 6-in-1 multi-purpose loader bucket is used for applications like loading, dozing, levelling, grabbing, spreading and backfilling. This is useful in construction sites for performing various applications, It provides maximum comfort, safety and noise reduction and meets ROPS /FOPS safety requirements. For operator flexibility, it offers air-conditioning*, ergonomic controls User-friendly consoles and ample storage space. GPS and GPRS-based remote tracking is attached with In-Site Monitors machine location and operations, which offers information about the machine and the fleet.

By Constro Facilitator